Киришүү: Акыркы убакта ата мекендик этиленгликол заводдору көмүр химиялык өнөр жайын кайра баштоо менен өндүрүштү комплекстүү конверсиялоонун ортосунда алмашып жатышат. Иштеп жаткан заводдорду ишке киргизүүдөгү өзгөрүүлөр рыноктогу суроо-талап менен сунуштун тең салмактуулугунун кийинки этапта кайрадан өзгөрүшүнө алып келди.

Көмүр химиялык өнөр жайы – бир нече кайра баштоо пландары

Учурда ички порттордо көмүрдүн баасы 1100дүн тегерегинде өзгөрүп турат. Экономикалык пайда жагынан ата мекендик жана чет элдик көмүр казып алуучу заводдор дагы эле жоготуу абалында, бирок кээ бир заводдор дагы эле аппараттардын перспективасына жараша кайра иштетүүнү пландап жатышат.

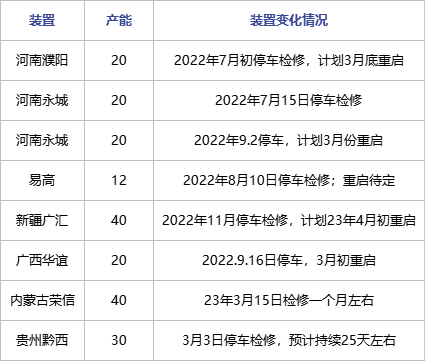

Учурдагы түзмөк планынан, өткөн жылы өчүрүлгөн бир нече түзмөктөр азыр Хунсифанг, Хуайи, Тианье жана Тяньин тарабынан кайра иштетилди; Кийинки этапта, Хэнань жана Гуанхуи да кайра баштоо пландары бар; Март айындагы капиталдык оңдоодон кийин Гуйчжоу Цянси апрель айынын башында кайра баштоону пландаштырууда. Апрель айынын колдо болгон ремонт планы борборлоштурулган эмес. Shaanxi Coal 1,8 миллион тонна жүк бирдигинин өсүшүнө кошумча, апрель айына көмүр химиялык өндүрүшүнүн жалпы планы 400000 тоннанын тегерегинде болушу күтүлүүдө.

Интеграция – жарым-жартылай накташуу, жарым-жартылай конвертация дагы деле байкалууда

Салттуу конверсия негизинен этилен кычкылы/этиленгликолдун өндүрүшүн жөнгө салууга негизделген. Этилен оксидинин учурдагы баасы 7200дүн тегерегинде. Бааны салыштыруу көз карашынан алганда, этилен кычкылын өндүрүүнүн экономикалык пайдасы учурда этиленгликолдон жогору. Бирок, этилен кычкылын сактоонун чектелүүсүнөн жана сууну редукциялоочу мономерлерге болгон учурдагы жалпак суроо-талаптан улам, көпчүлүк ишканалар этилен кычкылынын баасынын жогорулашына дуушар болушат, бирок сатууга тоскоолдуктар болуп жатат. Демек, салттуу технологиялык түзүлүштөрдүн кийинки этабында этилен гликолду кысуу жолу менен этилен кычкылынын өндүрүшүн көбөйтүү ыктымалдыгы өтө чектелген.

Ири кайра иштетүүчү жана химиялык заводдордун диверсификацияланган схемасы менен, кийинки этапта үч негизги ата мекендик кайра иштетүүчү жана химиялык интеграцияланган заводдордо этилендин ылдыйкы селективдүүлүгү үчүн оптималдаштырылган конфигурациялар жасалды. Мисалы, этилен оксидин көбөйтүү, ал эми ылдый агымда өзүн-өзү аралаштыруу, этилен керектөөсүн тең салмактоо үчүн стирол, винилацетат жана башка өнүмдөрдү кошуу. Апрелде, оор кайра иштетүү жана химиялык туруктуу күч тейлөө, Zhejiang мунай химиялык жана спутниктик жүктү азайтуу акырындык менен ишке ашты, бирок ишке ашыруунун конкреттүү даражасы дагы дагы тактоо керек.

Жацы приборлорду куруу кечиктирилиши мумкун

сүрөт

Азыркы учурда, Sanjiang жана Yuneng Chemical өндүрүшкө жаңы түзмөктөрдү коюуга жогорку ишеним бар; Өндүрүштүн ыктымалдыгы негизинен жылдын ортосунан кийин аныкталат. Башка приборлорду чыгаруунун так планы азыр жок.

Учурдагы камсыздоо жагындагы өзгөрүүлөргө жана келечектеги заводдун пландарына ылайык, полиэстер өндүрүшү марттан апрелге чейин салыштырмалуу туруктуу бойдон калат деп күтүлүүдө. Социалдык тең салмактуулуктун көз карашынан алганда малды жок кылуу дагы деле күтүлөт деп күтүлүп жатат, бирок малды жок кылуунун жалпы көлөмү салыштырмалуу чектелген.

Посттун убактысы: Мар-27-2023